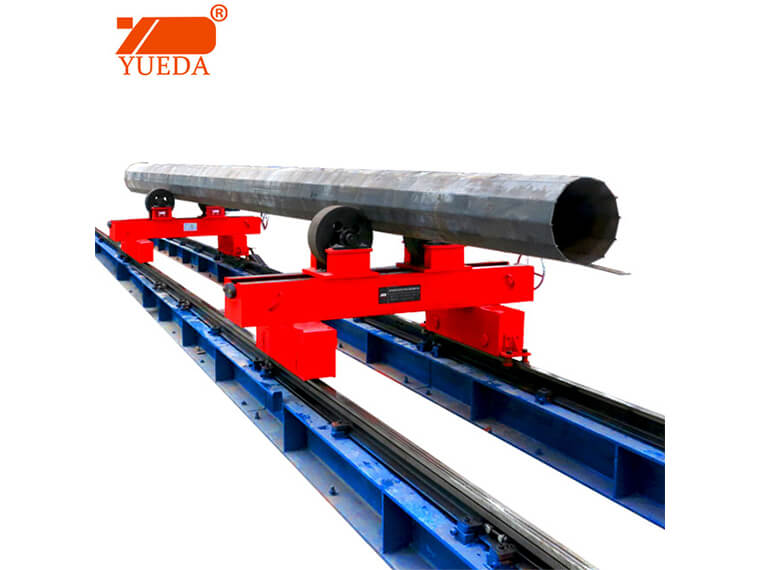

Hot sale KT series 2T 5T 10T conventional welding rotator

-

Price Range: $1,000.00 - $30,000.00 / Set -

MOQ: 1 Set/Sets (Min. Order) -

Model Number:- All Options

- KT-2

- KT-5

- KT-10

-

Lead Time:Quantity(Sets) 1 - 100 101 - 200 >200 Estimated Time(Days) 30 40 Negotiable -

Core strengths:1. 20 years manufacturer & trading company with powerful strength.

All Core Strengths

2. One stop solution provider.

3. OEM&ODM services are available.

4. Flexible payment terms:T/T,Cash,Western Union,L/C,etc.

- Tel +86 13838293687

- Email gm@yuedatech.com

Product description of KT series 2T 5T 10T conventional welding rotators:

Welding rotator also called as welding turning rolls and welding turning roller which is mainly used for cylindrical tank’s welding, polishing, rubber lining, assembling ,etc, and it’s also can match up with other tools for welding or assembling for cone and section equality solid of revolution. KT series 2T 5T 10T conventional welding turning rolls adjusted by lead screw manually, which is widely used for many industries such as wind powder, pressure vessel, petrochemical, pipeline, steel structure, boiler, surfacing welding rebuilding, etc.

Features and advantages of KT series 2T 5T 10T conventional welding rotators:

1. The 2T 5T 10T conventional welding rotator is composed of an motorized driving frame and a driven frame. The driving and driven frame are supported by shaped steel plate structure, with good comprehensive performance and large bearing weight. Roller frame base after welding through stress relief treatment, ensure long-term use without deformation.

2. The driving frame and the driven frame each have two rollers, which are mounted on the roller seat. The roller adopts integral roller, the surface of which is inlaid with polyurethane rubber, which can not only meet the bearing capacity of the workpiece, but also play a protective role on the workpiece. The roller has a large bearing capacity, good wear resistance, anti - aging, not easy to degum.

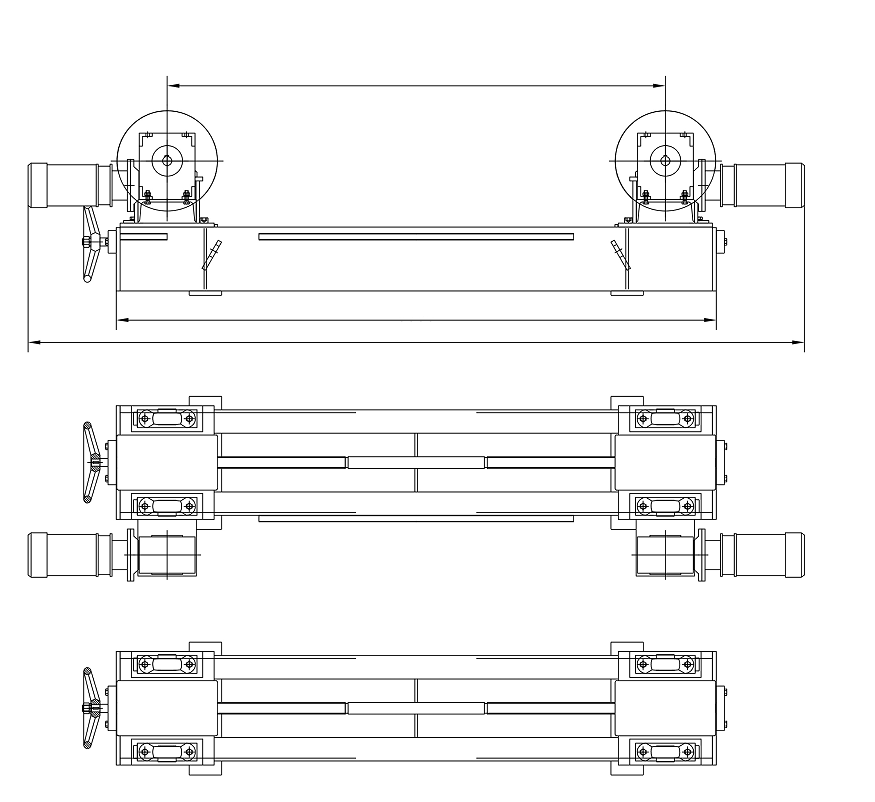

3.The adjustment center adopts lead screw to adjust the center distance of roller, which can adjust the center distance of two wheels to meet the requirements of different workpiece diameters, which is easy for operation.

4. Driving and driven frame each shaft hole a jig boring machine processing, axis parallelism is good, channeling momentum is small. Roller assembly is installed in the domestic well-known manufacturers of high quality bearings, the grease used in the bearing is lithium grease, with high lubrication performance.

5. The whole roller frame has strong rigidity and stability, beautiful appearance, reliable performance, simple maintenance, long service life.

6. The main color of the whole roller frame is beautiful and graceful. The roller frame has been carefully polished and priming before spraying the finishing paint, which has a good anti-rust ability.

7. Using frequency inverter stepless speed regulation control, high running accuracy, large starting torque, smooth running, with overvoltage, over current, overload, overheating and other protection functions.

8. The operating manual control box is equipped with the front, back, stop and speed adjustment functions of the roller, which is easy to operate and convenient.

9. Main electrics brand are Schneider and CHNT, frequency inverter brand is Schneider or Delta, motor, reducer and bearings brand are China famous brand.

Sketch drawing of KT series 2T 5T 10T conventional welding rotators:

-

- Any interest? Welcome to contact us to get details and professional quotation!

| Main parameters of KT series 2T 5T 10T conventional welding rotators | |||

| Model | KT-2T | KT-5T | KT-10T |

| Rated load | 2T | 5T | 10T |

| Worpiece diameter range | φ200-2000mm | φ200-2500mm | φ300-3000mm |

| Roller size | φ250x120mm | φ300x120mm | φ300x170mm |

| Roller type | PU | PU | PU |

| Roller linear speed | 100-1000mm/min | 100-1000mm/min | 100-1000mm/min |

| Drive motor power | 0.37KW*2 | 0.37KW*2 | 0.55KW*2 |

| Input voltage | 3 phase 220v/380v/415v/440v/460v, 50hz/60hz | 3 phase 220v/380v/415v/440v/460v, 50hz/60hz | 3 phase 220v/380v/415v/440v/460v, 50hz/60hz |

| Control mode | Electric cabinet with pendant controller or optional wireless remote controller | Electric cabinet with pendant controller or optional wireless remote controller | Electric cabinet with pendant controller or optional wireless remote controller |

Welcome your inquiry, welcome to visit us. One stop solution is ready for you!